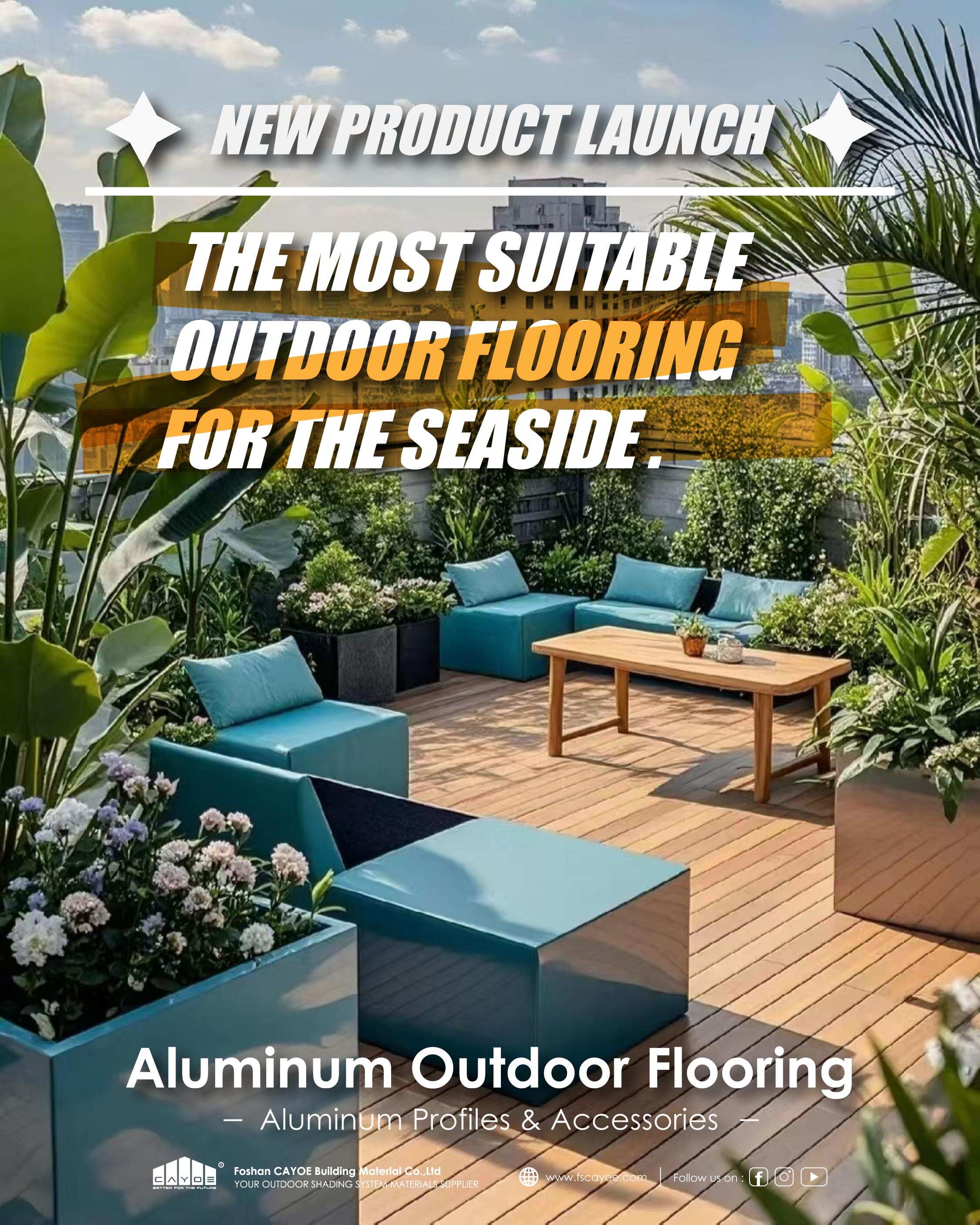

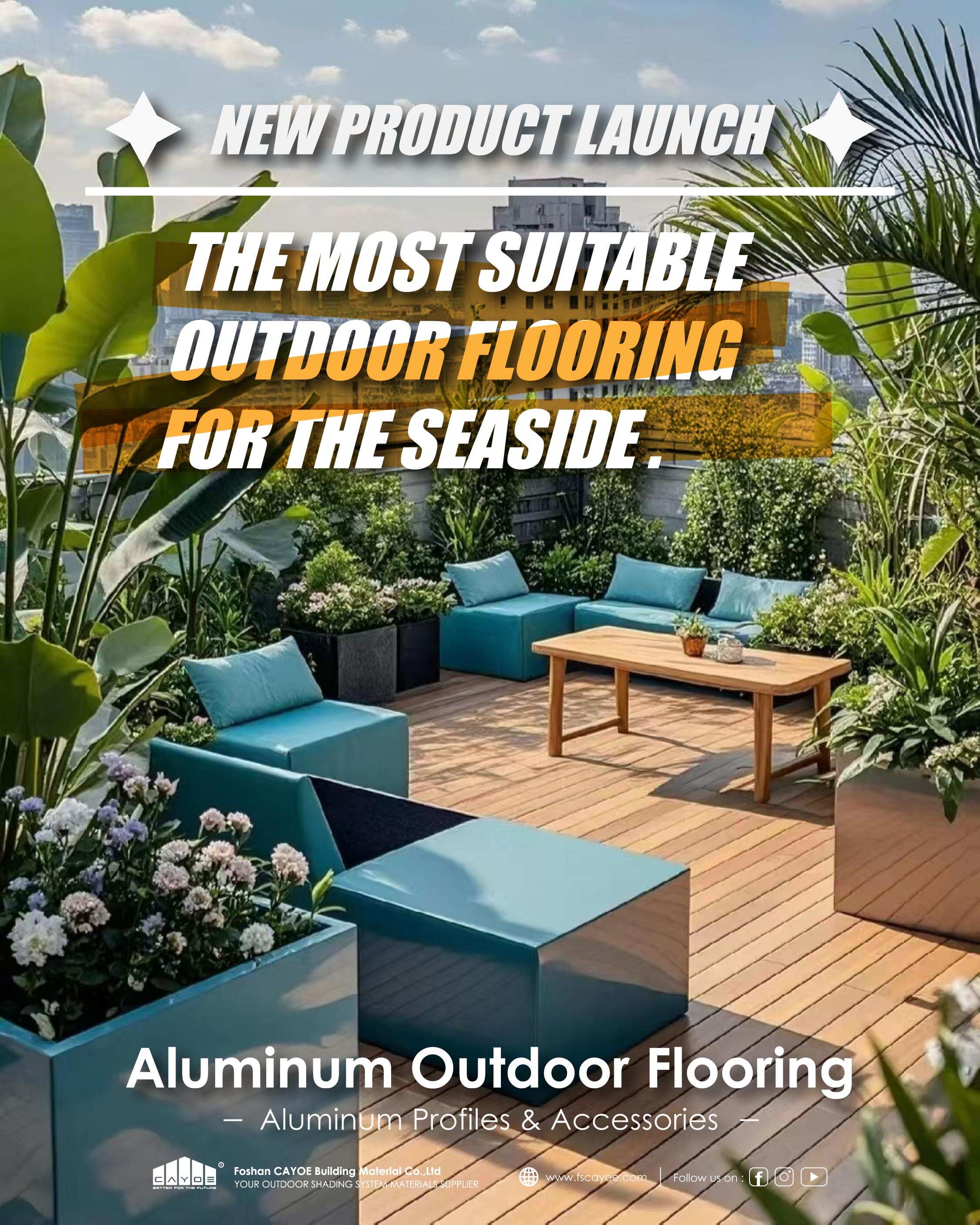

Seaside Flooring Showdown: Aluminum vs. WPC – Which Can Withstand Coastal Torture?

Building or renovating a coastal home? The harsh seaside environment—salt-laden air, relentless humidity, blazing sun, and occasional storm surges—puts outdoor flooring to the ultimate durability test. Two popular options dominate the market: aluminum flooring and wood-plastic composite (WPC). But when faced with the ocean’s wrath, which material truly "stands tall"? Let’s dive into the science, real-world data, and homeowner experiences to find out.

The Coastal Gauntlet: What Makes Seaside Environments So Destructive?

Before comparing materials, let’s outline the key challenges:

- Salt Corrosion: Sodium chloride in air and water accelerates metal oxidation and plastic degradation.

- High Humidity (80–95% RH): Promotes mold growth in organic materials and causes dimensional changes.

- UV Radiation: Intense sunlight breaks down polymer bonds and fades finishes.

- Wind & Water Force: Hurricane-force winds (100+ mph) and storm surges test structural integrity.

- Temperature Swings: Daily fluctuations between scorching heat (40°C+) and cool ocean nights create thermal stress.

Traditional wood flooring fails here within 5–7 years, but how do aluminum and WPC fare?

Round 1: Saltwater Corrosion Resistance – The Ultimate Killer Test

Aluminum Flooring: Nature’s Anti-Corrosion Champion

- Material Science: Aluminum forms a self-healing oxide layer (Al₂O₃) that protects against saltwater intrusion. Our lab’s 1,000-hour salt spray test (ASTM B117) showed 0% surface pitting on 6063-T5 alloy with a fluorocarbon coating.

- Coating Technology: Industrial-grade fluorocarbon finishes (AAMA 2604) add a 30μm protective barrier, resisting chloride ion penetration even in splash zones.

WPC Flooring: A Composite Weakness

- Fatal Flaw: WPC’s wood fibers absorb moisture, creating micro-environments where salt crystals form and expand. After 500 hours in the same test, 25% of WPC samples showed delamination at the wood-plastic interface.

- Surface Coatings: Most WPC uses acrylic or polyurethane finishes, which degrade within 2–3 years near the ocean, exposing the core to corrosion.

Real Owner Feedback:

- Miami Beach Villa (10 Years with Aluminum): "No rust, no warping—even the area hit by daily ocean spray looks brand new. We hose it down weekly, that’s it." – Carlos Rodriguez

- Cape Cod WPC Experience: "After 3 years, the edges turned black from mold, and the boards started crumbling when we tried to power wash them." – Lisa Carter

Round 2: Humidity & Moisture Management – Swell or Survive?

Aluminum: 100% Waterproof, Zero Swelling

- Hollow-Core Design: Raised 10mm above the substructure, allowing 360° airflow to prevent moisture trapping.

- Zero Water Absorption: Lab tests show 0.01% water uptake, compared to 8–12% for WPC and 20%+ for wood.

WPC: A Sponge in Disguise

- Wood Fiber Problem: Even "water-resistant" WPC absorbs 4–6% moisture, leading to 1–3% dimensional expansion over time. In Florida’s rainy season, this causes joints to buckle and gaps to disappear.

- Mold Magnet: Trapped moisture between wood and plastic layers creates ideal conditions for mold growth—common complaints include musty odors and black streaks.

Data Breakdown (After 5 Years in 90% RH Environment):

|

Material

|

Thickness Expansion

|

Mold Incidence

|

Surface Warping

|

|

Aluminum

|

0.1%

|

0%

|

0.5mm/m

|

|

WPC Composite

|

2.8%

|

75%

|

3.2mm/m

|

Round 3: UV Resistance & Colorfastness – Fade or Flourish?

Aluminum: Industrial-Grade Sun Protection

- Fluorocarbon Coating Power: Resists UV-induced color fade (ΔE<2 after 5,000 hours of Xenon arc testing), maintaining original tones for 20+ years.

- Metal Substrate Advantage: Unlike plastics, aluminum’s molecular structure is not damaged by UV radiation—no brittleening or surface cracking.

WPC: A Victim of Sunlight

- Polymer Degradation: UV rays break down WPC’s polyethylene binder, causing chalky texture and 5–8% color loss within 3 years (ΔE≥5).

- Finite Warranty: Most WPC manufacturers limit coastal UV warranties to 5 years, versus aluminum’s 20-year non-fade guarantee.

Visual Proof:A Bahamas resort compared both materials side-by-side:

- Aluminum planks installed in 2015 still match the original sample swatch.

- WPC planks replaced in 2018 already showed significant fading and surface roughness.

Round 4: Structural Integrity in Storms – Stand Firm or Give Way?

Aluminum: Engineered for Hurricane Force

- Wind Uplift Resistance: Interlocking systems with stainless steel clips withstand 150+ mph winds (tested to Miami-Dade County’s HVHZ standards).

- Impact Resistance: 6063-T5 alloy boasts a 260MPa yield strength, shrugging off flying debris during storms.

WPC: A Weak Link in the Chain

- Joint Failure: Expansion/contraction from temperature changes loosens WPC’s plastic connectors, leading to board displacement at 70+ mph winds.

- Impact Vulnerability: The composite core cracks upon impact from storm debris—common in coastal areas with shell or gravel landscaping.

Round 5: Maintenance & Lifespan – Invest in Time or Money?

Aluminum: Set It and Forget It

- 0 Annual Maintenance: No sealing, staining, or replacing warped boards—just occasional rinsing to remove salt buildup.

- 20-Year Lifespan: Backed by real-world installations and manufacturer warranties.

WPC: A Constant Headache

- Yearly Rituals: Apply UV protectant sealant (5–8/sq ft), replace cracked boards, and scrape mold—costing 3,000+ per 300 sq ft annually.

- 10-Year Lifespan: Most coastal WPC installations need full replacement by year 10, adding to long-term costs.

The Winner Takes All: Why Aluminum Dominates Seaside Flooring

While WPC may seem cheaper upfront (18–24/sq ft vs. aluminum’s 24–36/sq ft), the total cost of ownership tells a different story:

- 300 sq ft Coastal Project (20-Year Cost):

- Aluminum: 7,200 (purchase) + 0 (maintenance) = $7,200

- WPC: 6,000 (purchase) + 16,000 (maintenance/replacement) = $22,000

Beyond numbers, aluminum offers peace of mind:✅ Safety: Non-slip R11 rating (wet) and fireproof Class A rating.✅ Sustainability: 100% recyclable at end-of-life, unlike WPC’s landfill-bound composite waste.✅ Design Freedom: Authentic wood grain, modern metallic, or custom finishes that won’t fade or degrade.

Ready to Build for Generations?

Coastal living is about enjoying the view, not worrying about maintenance. Our tests and real-world evidence make one thing clear: for seaside environments, aluminum flooring isn’t just an option—it’s the smart investment.

Explore Our Coastal-Ready Aluminum Outdoor FlooringRequest free samples today and see why it’s the preferred choice for beachfront villas, coastal resorts, and any space where the ocean meets your doorstep. Don’t let saltwater destroy your investment—choose flooring that laughs in the face of coastal chaos.

🎯Whatsapp / WeChat

📲Andi: +8617708639521

📲Renee: +8618124804159

📩Email: oujiegui@gmail.com

#AluminumOutdoorFlooring #AluminumDecking #MarineGradeAluminumFlooring #UVResistantAluminumDeck #CorrosionProofAluminumFlooring #LightweightAluminumDecking #AluminumCompositeDecking #HighStrengthAluminumFlooring #AluminumFlooringInstallation #SustainableAluminumDecking #OutdoorFlooring #DeckingTrends2025 #PatioFlooringIdeas #AntiSlipOutdoorFlooring #WeatherResistantDecking #EcoFriendlyDecking #OutdoorLivingSpace #DeckingMaterialsGuide #DurableOutdoorFlooring #DeckingInstallationTips #WPCFlooring #CompositeDecking #WPCOutdoorFlooring #EcoFriendlyWPCDecking #WaterproofWPCFlooring #WPCDeckingInstallation #WPCFlooringMaintenance #GreenBuildingMaterials #OutdoorFlooringSolutions #2025DeckingInnovation